- Qingqingquan

- Shandong, China

- 20 days

- 300 units per month

This article systematically reviews the development history of the core technologies of water treatment equipment

The Leap Of Water Treatment Equipment From Traditional Filtration To Intelligentization(Ⅰ)

With the increasing global water shortage and environmental pollution problems, the role of water treatment equipment in municipal water supply, industrial wastewater treatment, seawater desalination and other fields has become increasingly critical. From the early simple sedimentation and sand filtration to today's reverse osmosis (RO) and intelligent monitoring systems, water treatment technology has undergone a revolutionary upgrade.

This article will take stock of the core technologies of water treatment equipment, analyze the leapfrog development of traditional methods and modern intelligence, and look forward to future trends.

1. Traditional water treatment technology: basic but irreplaceable

Before the rise of intelligent technology, traditional water treatment methods laid the foundation for the industry and still play an important role in many scenarios.

1. 1 Physical filtration technology

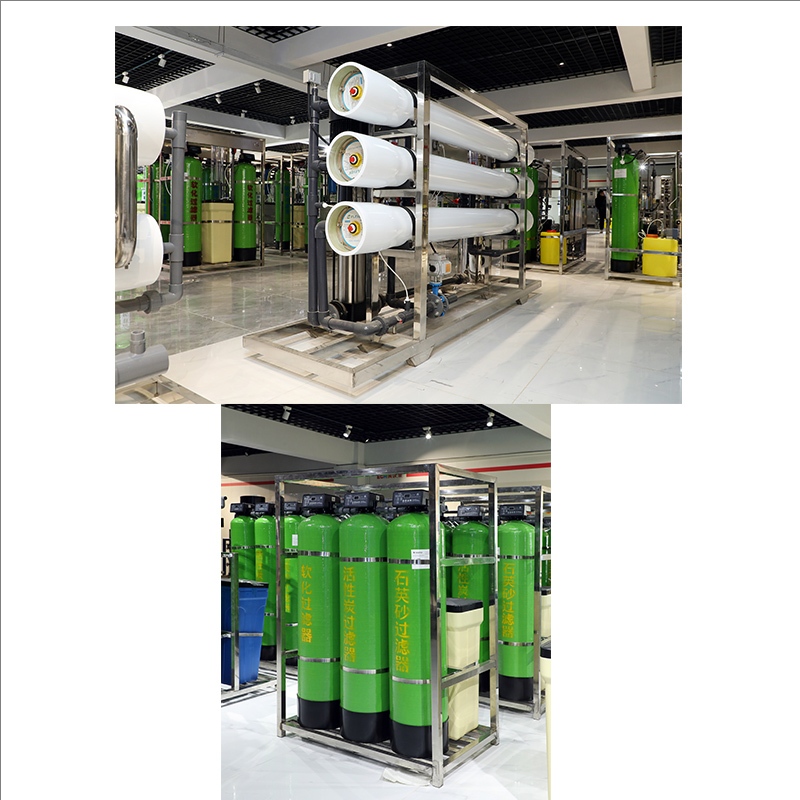

Sand filtration and multi-media filtration: using materials such as quartz sand and activated carbon to remove suspended matter and colloids, suitable for the pretreatment stage.

Sedimentation and flotation: separating impurities by gravity sedimentation or bubble adsorption, commonly used in sewage treatment plants.

1.2 Chemical treatment technology

Coagulation-flocculation: adding agents such as aluminum salts and iron salts to aggregate tiny particles into large particles for easy filtration.

Chlorine disinfection: low cost, simple operation, but may produce carcinogenic byproducts (such as chloroform).

1.3 Biological treatment technology

Activated sludge method: using microorganisms to degrade organic matter, widely used in municipal sewage treatment.

Biofilm method (such as BAF): microorganisms attached to the filler, higher treatment efficiency, smaller footprint.

Limitations: Traditional technology relies on manual operation, high energy consumption, and limited treatment capacity for complex pollutants (such as heavy metals, PFAS).